Modifying the Laser Cut

Once a part is imported and the clean-up of the part is complete, the part is ready to be tooled. Once tooled, modification of the Laser Cut of the part can be done by the user. Selecting a part of the laser tooling will display the laser-cut dialogue.

Reverse – This option will reverse the direction of the laser cut, selecting again will return the laser cut to the default direction.

Delete – This option will delete the selected tooling.

Pierce – The drop-down options are to select which Pierce type is to be used. Possible pierce types will vary depending on the machine being used. Depending on the choice of pierce type, the marker drawn to show the pierce point in the editor will change.

Condition – This is the Laser condition to be applied on this cut. A laser condition will refer to the laser cutting parameters such as power and feed rate. To use different conditions for different sections of the cut, select the Switch Contour Size option in the Advanced section below.

Contour – This is a navigation option which will navigate to different contour-level options such as adding/removing microjoints.

Similar – This option will select all identical laser cuts in the part. For example, laser tooling of all 10mm size squares can be selected.

All Laser Cuts – This will select all the laser cuts in the part for editing.

Approach

Length – This is the length of the approach cut to the part.

Radius – This is the radius desired in the approach cut to the part. Note that the approach length will automatically change when increasing the radius and could shorten the straight segment of the approach geometry.

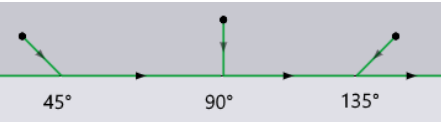

Angle – This is the angle desired for the approach cut to the part.

Dimple – This is a quality feature for the approach and withdrawal to create a dimple. Dimple/Through approaches will be used when the user does not want any kink sticking out from the edge on which the approach was made. The depth of the dimple is internally calculated based on material thickness & micro joint length using the following table:

| Micro joint Length (mj) in mm | Dimple depth in mm |

| Up to 4mm | 0.06 * mj + 0.58 |

| Up to 0.7mm | 0.6mm |

| From 0.7mm to 2.7mm | 0.06 * mj + 0.58 |

| From 2.7 | 1.7mm |

| Up to 1.5mm | 1.2mm |

| From 1.5 to 2.7mm | 0.82 * mj + 0.04 |

| From 2.7mm | 2.4mm |

Withdrawal

Withdrawal – This checkbox will turn on or off a laser cut withdrawal from the part.

Length – This is the length of the withdrawal cut from the part.

Radius – This is the radius desired in the withdrawal cut from the part.

Angle – This is the angle desired for the withdrawal cut from the part.

Micro joint

Microjoint – When checked, a microjoint will be added at the end of the cut.

Width – This is the length of the microjoint to be added.

Advanced

Beam Offset – The beam offset is to ensure the dimensional accuracy of parts. The following options can be chosen:

- By Controller – This is the standard behaviour, the offset is computed by the machine controller.

- By Software – The offset is precomputed by the software.

- None – No beam offset. The centre of the beam will be on the drawing path.

Switch Contour Size – This allows for different laser cutting conditions for sections of the cut.